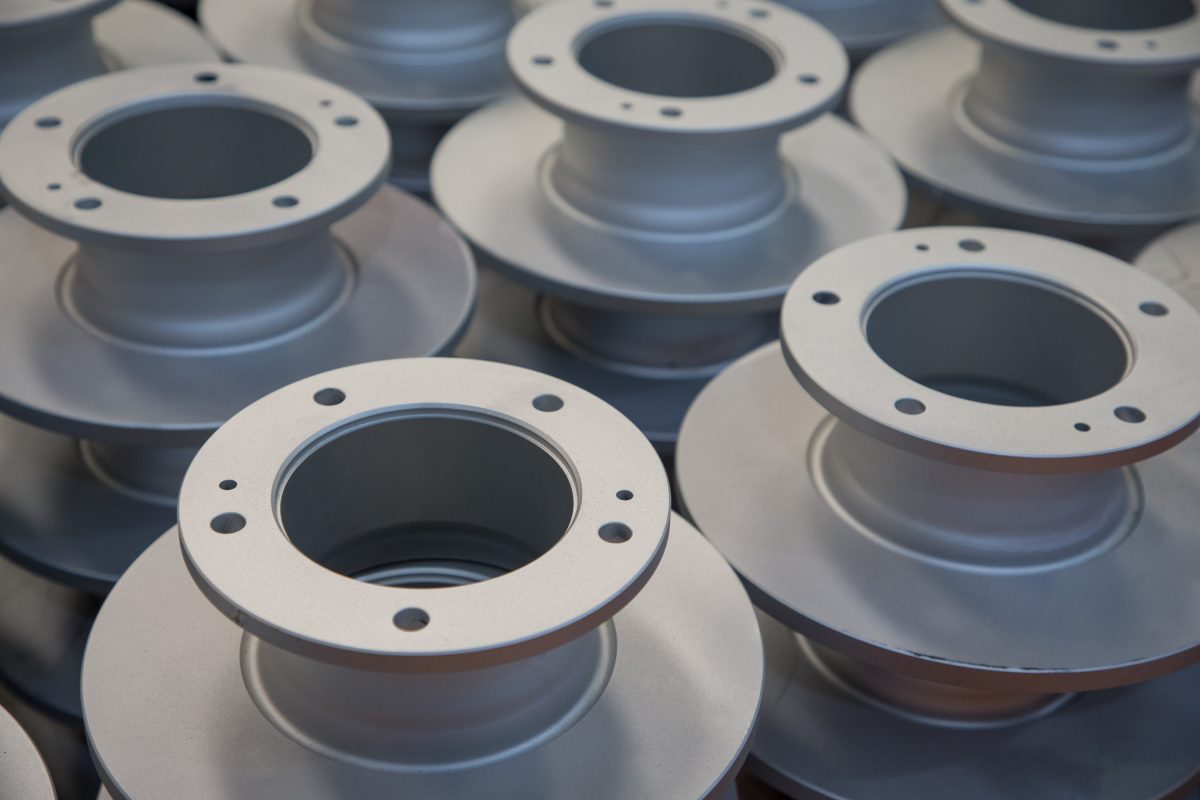

The Anochrome Group has a number of dip-spin coating lines, as well as automated spray coating lines and a manual facility for large or awkward items.

These coatings are often used with a top coat that can improve corrosion resistance, give barrier protection, or act as a torque control or modifier, such as the Magni® System, Delta MKS® from Dörken®, and Geomet® from NOF® Metal Coatings (formerly Dacral®).

The dip spin process involves placing the items to be coated into a perforated basket, the basket is then submerged into a tank containing the coating material, the basket is then removed for the material and then spun at a relatively high rpm to expel excess material. The planetary motion or tilts mechanism is designed to re orientate the parts during the spinning cycle so as to release coating material that would otherwaise be trappped in recesses etc. This then reduces the levels of recess infill that would otherwise be present in a standard dip spin coating process.

Parts can be processed using automatic CNC programed robotic equipment, this may require initial investment in bespoke tooling.

Parts processed with manual input, generally means reduced capital outlay on bespoke tooling.

If you'd like to enquire about any of our services or if you just have a question, please let us know

© 2024 Anochrome Group Privacy Policy Web Design by Bluelight